Case Studies

For over a decade, we’ve supported mid-sized manufacturers in their digital transformation with SAP Business One PRODUCTION — from process analysis to go-live.

100+ successful ERP rollouts show:

Go behind the scenes

Customer interviews by industry

Interview with Belizar Pakic | Managing Director Pakic GmbH

Mr. Pakic, why did you choose SAP Business One with SMS as your partner?

An important factor for us was protecting our investment for the future—and only SAP offers that at this level. From a technology perspective, it’s about control capabilities: the granularity of production control in SAP Business One PRODUCTION for the metalworking industry is unmatched. And SMS as our partner? Because they understand us and our business.

How has your day-to-day operation changed with the new solution?

FIn the past, everyone talked about the paperless office — now we have it. With SAP Business One PRODUCTION, we’re fully digital. Paper in production is an error source. We now manage entirely without paper. That minimizes errors, because every piece of paper represents the time it was printed; from that moment, the information begins to age. With SAP Business One PRODUCTION, our data is always current.

What does that mean for your customers?

Order handling now runs at a much higher level of quality. We supply both new products and spare parts, so we have to reference both historical and current revision levels. Previously, this was heavily people-dependent—employee X knew what customer Y needed. Today, the system tells us.

And for the future?

With SAP Business One PRODUCTION, we will capture and document all of our company knowledge in the system, making it available to everyone who needs it. Our manufacturing will continuously improve, become more tailored to each customer, and remain more transparent. What more could we ask for?

REICH Thermoprozesstechnik GmbH

REICH Thermoprozesstechnik GmbH — Shaping the future of manufacturing

TTradition alone does not make a successful plant manufacturer; it is the foundation on which we build our continued development as a business. Our stated goal: to create genuine value for our customers and their processes through expertise and innovation.

The prerequisite is a detailed understanding of product and process requirements. Only those who truly know the challenges can develop solutions that prove themselves in day-to-day operations.

Since the acquisition by Tobias Layer and Steffen Jaiser on July 1, 2013, REICH Thermoprozesstechnik GmbH has developed impressively. After an initial expansion in 2016, the company—driven also by international growth—again reached its capacity limits.

In early 2019, REICH launched a comprehensive optimization and expansion program covering sheet-metal production, assembly, control-cabinet manufacturing and warehouse operations. The result: a modernized production area of around 9,000 m², improved material flow, significantly shorter transport routes, and an end-to-end digital process landscape.

“This was only possible with a software foundation that adapts flexibly to our processes,” says Steffen Jaiser. Since 2013, REICH has relied on SAP Business One - PRODUCTION as a future-proof solution for integrated manufacturing processes.

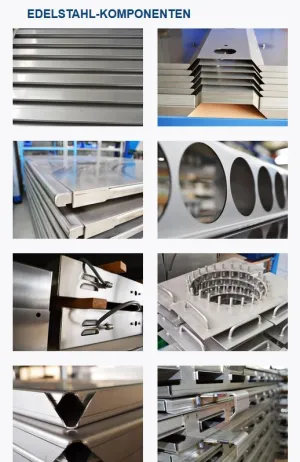

Interview with Erwin Fritz Jaiser — Owner of E. F. Jaiser Blechbearbeitung

Mr. Jaiser, you took over a company in difficult times and led it to success under your leadership. What’s your credo?

We have always focused on quality—and I don’t just mean the product, but also our employees’ quality of life. We have top people here and a genuinely warm, friendly atmosphere. To keep it that way, we grow deliberately and at a measured pace. I also value trusting, long-term relationships with customers more than quick, lucrative deals. It pays off—our first customer from 1981 is still with us.

What sets your company apart?

We rely on state-of-the-art equipment—from the laser cutting system to the press brake. And our experts from every area work closely together. On major projects, the welder collaborates with the design engineer, or the surface-finishing specialist compares notes with the punching-machine expert. That’s how the best products are made—but you also need flawless processes across the company to support that.

How do you make sure everything runs smoothly when things get busy?

With modern technology as well — SAP Business One PRODUCTION for the metalworking industry from SMS. Processes are clearly defined, and every employee knows what to do, when, and how. I myself gain deeper insight into my own business. If a long-standing customer asks for a discount, I quickly check the system: I can see what a given assembly costs and how long each manufacturing operation takes. So I immediately know our margins and what we need to charge—whether we produce 2, 20, or 200 units.

JÜCKER GmbH & Co. Stahlhandels KG

Markus Jücker — Managing Director, JÜCKER GmbH & Co. Stahlhandels KG

“They know my business and my markets.”

“Today we move 50% more with the same team.”

Since 2000, Markus Jücker has led the third-generation family business JÜCKER GmbH & Co. Stahlhandels KG in Dülmen. What began as a one-man operation in its pioneering years has grown into a leading player in the sector, combining innovation with Westphalian pragmatism to the benefit of its customers. Accordingly, the bar for the company’s IT is set high.

Interview with Markus Jücker

Mr. Jücker, what prompted you to look for a new software solution for your company?

Our old software served us well for many years. Unfortunately, it wasn’t really being developed further and it didn’t cover all areas of the business. When the time came to change, we chose to completely realign our approach.

Speaking of future-proofing: is that why you decided on SAP Business One?

That was certainly a key factor. We assume that a company as established as SAP will keep evolving its solutions—and that we will benefit from that progress. It was also important to us to get a complete software package for all of our processes from a single source.

Good software shouldn’t just meet requirements—it should also be a driver of business success...

Absolutely. We reworked our pricing strategy in many areas, and our pricing is now much more tailored to each individual case. Today we can represent trading, production, and engineering in one integrated solution, which lets us realize cost advantages for our customers. Processes run much faster, workflows have improved significantly, and administration is handled by the system with a high degree of automation.

What criteria did the new solution need to meet?

I should preface this by saying the steel trade is very diverse. There are pure traders—some specialists, some generalists—companies operating nationally and internationally, and there are value-add processors, which we are ourselves with two business units. It was crucial that we could handle all business areas—pure trading and value-added processing—within one integrated system. And of course, that we would get a future-proof solution..

And why work with SMS?

As I said, steel trade is not one-size-fits-all. Companies in this sector are often highly individual. For us it was essential that our partner could cover the full breadth of steel-trade processes competently—not just pure trading, but also value-added processes such as steel construction processing and rebar bending. Only someone who knows and understands these processes can implement a solution that truly meets expectations.

So SAP Business One with SMS is the right solution for you?

We are very satisfied with the decision

and would make the same choice again today.

Get in touch — no obligation